Corrosion Warning!

Corrosion can and will damage your ladders.

Rivet Problem

We found that nine out of sixteen rivets holding the roof hooks to a roof ladder failed due to a corrosive condition under the rivet heads. There was also excessive corrosion on the roof hook itself.

Screwdriver Test

Surface corrosion may indicate internal corrosion. One way to test the rivet condition is to bump each rivet with the flat head of a screwdriver.

Spike Problem

The spike on the butt of a 24-foot two-section extension ladder became so corroded that the spike pulled right out of the ladder.

We will look for these problems when we test your ladders. Due to the nature of this problem, however, we need you to inspect your ladders between our annual tests. We recommend you check your ladders on a weekly basis – perhaps when you do your weekly truck inspection.

Update

Rung Plate Problem

This picture shows a "rung plate" with four rivets holding the plate to the ladder beam. Duo-Safety welds their rungs to the beams. Subsequently, a rivet head missing at a rung connection is not critical, but should be repaired.

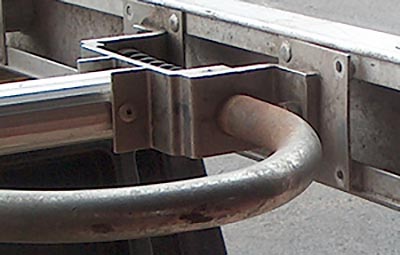

Lock Assembly Problem

This picture showing a lock assembly is another critical location. Again the bolts go through the plates that rivet to the beam. Rivet failure means the extension lock assembly may fail.